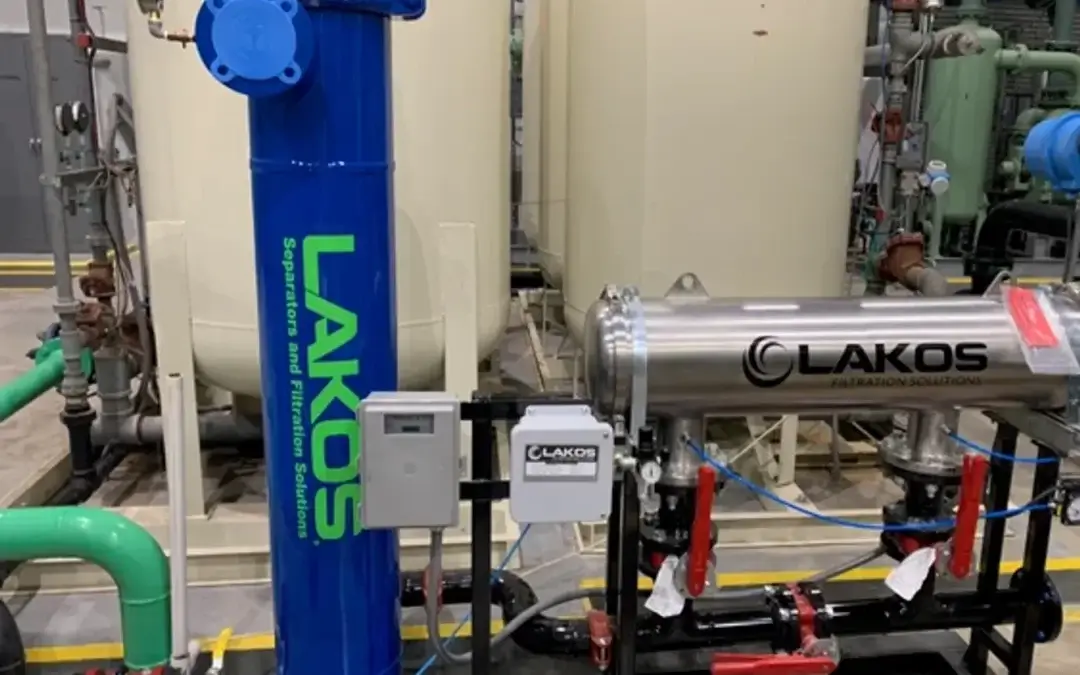

In the realm of industrial filtration and separation systems, Lakos Industrial Separators stand out as a vital component that plays a crucial role in maintaining efficiency, reducing costs, and promoting sustainability. With a myriad of benefits ranging from pre-filtration to protecting heat exchangers, these separators have become indispensable in various industrial processes.

Today, we’ll walk through exactly why and how Lakos Industrial Separators

Industrial Separators = Pre-Filtration Excellence

One of the key advantages of incorporating a Lakos Separator into your industrial setup is its ability to act as a pre-filter before finer filtration mechanisms. This simple step yields a plethora of benefits, such as reducing disposal costs, minimizing labor and maintenance downtime, and extending the life of fine filtration and water treatment systems. By effectively removing larger solids early in the process, Lakos Separators help in protecting subsequent filters, thereby preventing clogging and enhancing overall efficiency.

Spray Nozzle Protection

Clogging of spray nozzles can be a frequent headache in industrial settings, leading to inefficient spray coverage and increased maintenance costs. Lakos Separators come to the rescue by eliminating solids that clog these crucial components. By maintaining the original design of the nozzles and preventing wear and abrasion, these separators contribute to consistent spray patterns, reduced replacement frequency, and overall cost savings.

Sump and Basin Maintenance

Solids accumulation in sumps and basins can lead to a host of issues, including increased downtime, the growth of microbes, and the need for excessive chemical treatments. Lakos Separators effectively minimize such problems by removing solids before they settle. This results in fewer shutdowns, decreased cleanout times, and a more stable process liquid environment that promotes longevity and efficiency.

Heat Exchanger Protection

Heat exchangers are essential components in many industrial processes, and fouling can significantly impact their efficiency and lifespan. Lakos Separators offer reliable protection against fouling by removing suspended particles like grit, dirt, and scale. By maintaining design efficiencies, reducing maintenance needs, and enhancing heat transfer rates, these separators contribute to smoother operations and cost savings.

Waste Reduction and Sustainability

One of the standout features of Lakos Separators is their ability to reduce waste and promote sustainability. By removing solids from liquids, these separators enable the reuse of valuable liquids, reduce disposal costs, and extend the life of processed liquids. Additionally, the concentration of solids for easy disposal or recovery of high-value materials further enhances the economic and environmental benefits of using Lakos Separators.

Industrial Separators can really come in handy!

Lakos Industrial Separators serve as indispensable tools in enhancing efficiency, reducing maintenance costs, and promoting sustainability in industrial processes. From pre-filtration to protecting critical components like heat exchangers and spray nozzles, these separators champion a holistic approach to filtration and separation that benefits both operations and the environment. Embracing Lakos Separators is not just a smart business decision; it’s a step towards a more efficient, cost-effective, and sustainable industrial future.

East Coast Filtration is proud to be the lead distributor of Lakos products. To learn more, browse our selection of Lakos products or visit their website to learn more.